Symtech SCA-1 Headlight Aimer

I f you've been approached by the State of NH pertaining to headlight aimers they are in such demand, even the manufacturer is way behind. We have orders coming in for the SCA-1 Symtech headlight aimer, please contact us if you have a need at 603-234-2612. We can verify the delay in obtaining the product due to the demand that's been placed. Headlight aiming is part of inspection process and is required by the state. This is not only a NH requirement, but other states as well. Please see the end of this blog for a list of states that require headlight aimers. We have been flooded with calls at this time. We have an order of 10 coming in, and have already sold 8. We would be glad to add you to our list for when they come in. Call Clark at 603-234-2612. Our shipment of 10 will arrive to our shop by August 1.

f you've been approached by the State of NH pertaining to headlight aimers they are in such demand, even the manufacturer is way behind. We have orders coming in for the SCA-1 Symtech headlight aimer, please contact us if you have a need at 603-234-2612. We can verify the delay in obtaining the product due to the demand that's been placed. Headlight aiming is part of inspection process and is required by the state. This is not only a NH requirement, but other states as well. Please see the end of this blog for a list of states that require headlight aimers. We have been flooded with calls at this time. We have an order of 10 coming in, and have already sold 8. We would be glad to add you to our list for when they come in. Call Clark at 603-234-2612. Our shipment of 10 will arrive to our shop by August 1.

UPDATE: We have placed a second order that will be in later in August.

Saf-C 3206.02 Minimum Space Requirements Each inspection station shall:

- Have a testing space that has no obstructions and is large enough for a mechanic to walk around a vehicle with its doors open;

- Be a minimum of 12 feet by 25 feet in length, if the station inspects motor vehicles;

- Be a minimum of 12 feet by 50 feet in length, if the station is equipped with a headlight testing screen or board; and

- Be a minimum of 8 feet by 12 feet in length, if the station inspects only motorcycles

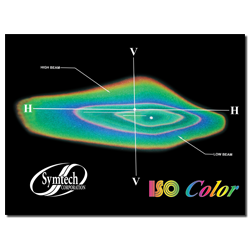

Saf-C 3206.04 Tools and Equipment Each inspection station shall have the following tools and equipment: A brake drum gage; A gauging device to measure the thickness of brake pads; A ball joint gauge; A lift or jack, capable of hoisting a vehicle to check its: Ball joints; Suspension linkage; Wheel play; Exhaust system; Undercarriage; and Frame of the vehicle; Tools necessary for the proper assembly and disassembly of any parts, which shall include: Hammers; Portable lights; Socket sets, including metric sizes; Wrenches, including open and box end; Screwdrivers; and Electrical test lights; Headlight aimer(s) or headlight board capable of determining the proper headlight angle of all vehicles to be inspected; Tint meter, if the station inspects vehicles with tinted glass; An on-board diagnostic scan tool capable of communicating with all model year 1996 or newer on-board diagnostic equipped light-duty vehicles and light-duty trucks; and any other tools necessary to conduct a proper vehicle inspection.

Additional Tools for Motorcycle Inspection Stations

- Wheel truing stand.

- Drive chain tool.

- Decibel meter.

- Assorted bulbs and lenses.

- Center punches.

Information courtesy of Inspection Station Requirements posted on NH.gov. STATE APPROVED HEADLIGHT AIMER USA regulated states - headlamp alignment include California, Connecticut, Delaware, Hawaii, Maine, Mississippi, New Hampshire, North Carolina, Pennsylvania, Rhode Island, Utah, Vermont, Massachusetts, District of Columbia, and West Virginia.

Level optical head by rotating eccentric wheel at rear of base until level vial registers "level."

Level optical head by rotating eccentric wheel at rear of base until level vial registers "level."